- Pregled

- Povezani proizvodi

Маркетиншке активности

Opis proizvoda

stavka |

Infracrvena indukciona noćna lampa sa punjivom baterijom, senzor, LED svetlo za ormar, PIR pokretna LED svetla za kabinete i garderobe |

Broj modela |

NL2 |

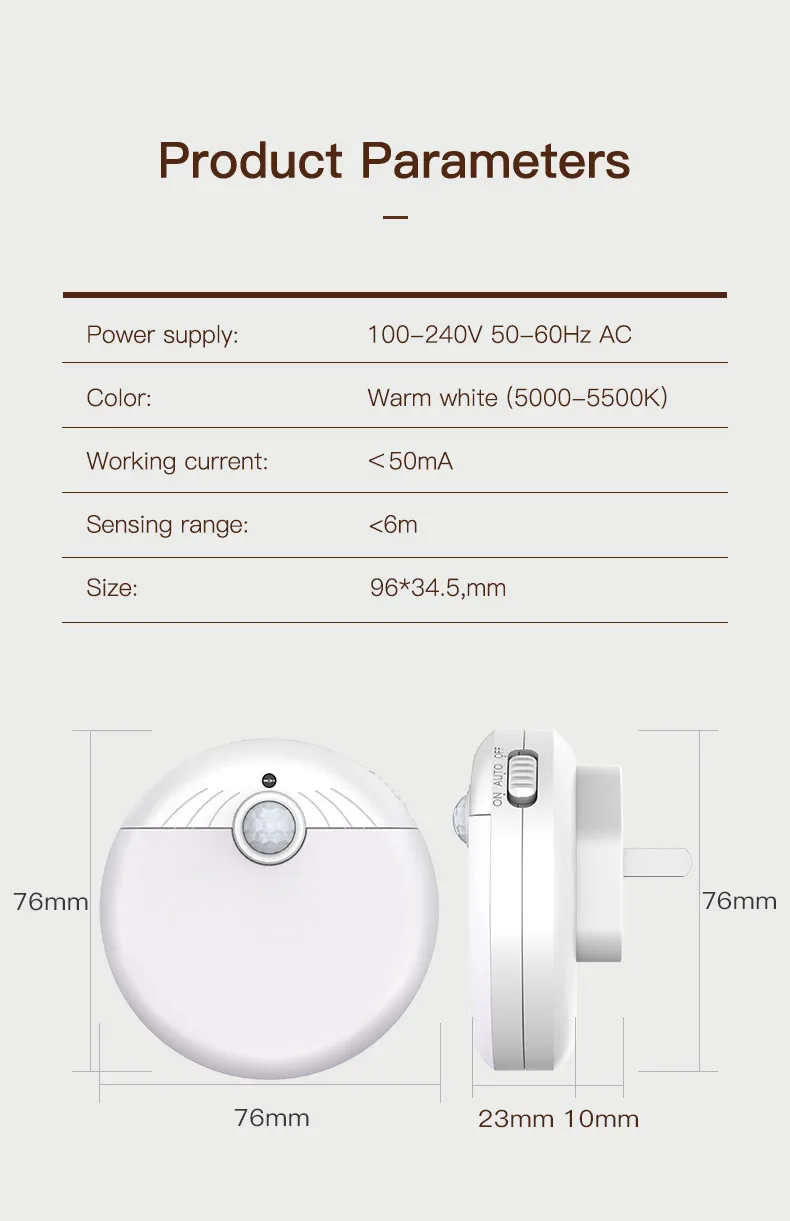

Извор енергије |

110-240V AC/3*AAA baterija |

Karakteristika |

Senzorom kretanja |

Коришћење |

Može se koristiti u mraku |

Tip |

Prijenosna, punjiva |

Funkcija |

Za osvetljavanje |

ČPP

П1: Који су услови плаћања за нове купце?

О: Обично трговинско осигурање, опционо ће бити кредитна картица, виза, е-провера, Вестерн Унион или Т/Т.

П2: Шта је са временом испоруке?

О: 3-5 дана за ред стазе и 10-15 дана за масу.

П3: Како шаљете робу и колико времена је потребно да стигне?

О: Обично шаљемо ДХЛ, УПС, ФедЕк или ТНТ. Обично је потребно 3-5 дана да стигне. Отпремање од ваздуха до врата траје око 15 дана.

П4: Могу ли да одштампам свој лого на уређају и пакету?

О: Да, НЕ МОК за штампање логотипа на уређају и пакету.

К5. Има ли сертификата за ваше производе?

-- ЦЕ, РОХС, ПСЕ, Реацх, УКЦА итд., тако да се могу безбедно продати широм света!

К6. Како наставити са наручивањем лед светла?

О: Прво, обавестите нас о вашим захтевима или апликацији. Друго, цитирамо према вашим захтевима или нашим сугестијама. Треће купац потврђује узорке и ставља депозит за формалну наруџбу. На крају, организујемо производњу.

П7: Како шаљете робу и колико времена је потребно да стигне?

О: Мала поруџбина би била испоручена међународним експресима (3-7 дана) или међународном логистичком пошиљком (15-20 дана). Групна наруџба би се испоручила авиокомпанијом (5-7 дана од аеродрома до аеродрома) и поморском доставом (20-40 дана ДДП)

П8. Како наше пословање чините дугорочним и добрим односом?

-1.конкурентна цена да би вин-вин

-2. чувајте тајне за нашег кооперативног купца

-3. Пошаљите нове замене са следећом наруџбом за све неисправне.