Petite lampe de table LED ronde de luxe pour décoration intérieure avec chargement USB pour utilisation en chambre, extérieur, restaurant 80 Ra rendu de couleur

- Aperçu

- Produits connexes

Activités de marketing

Description des produits

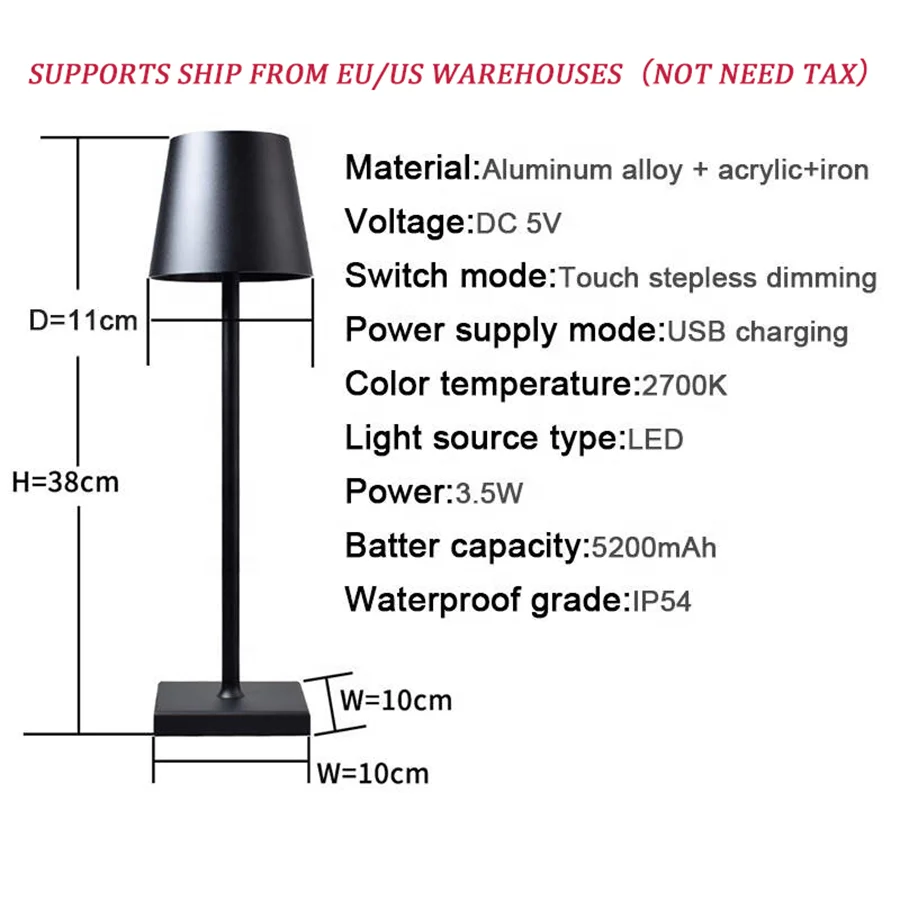

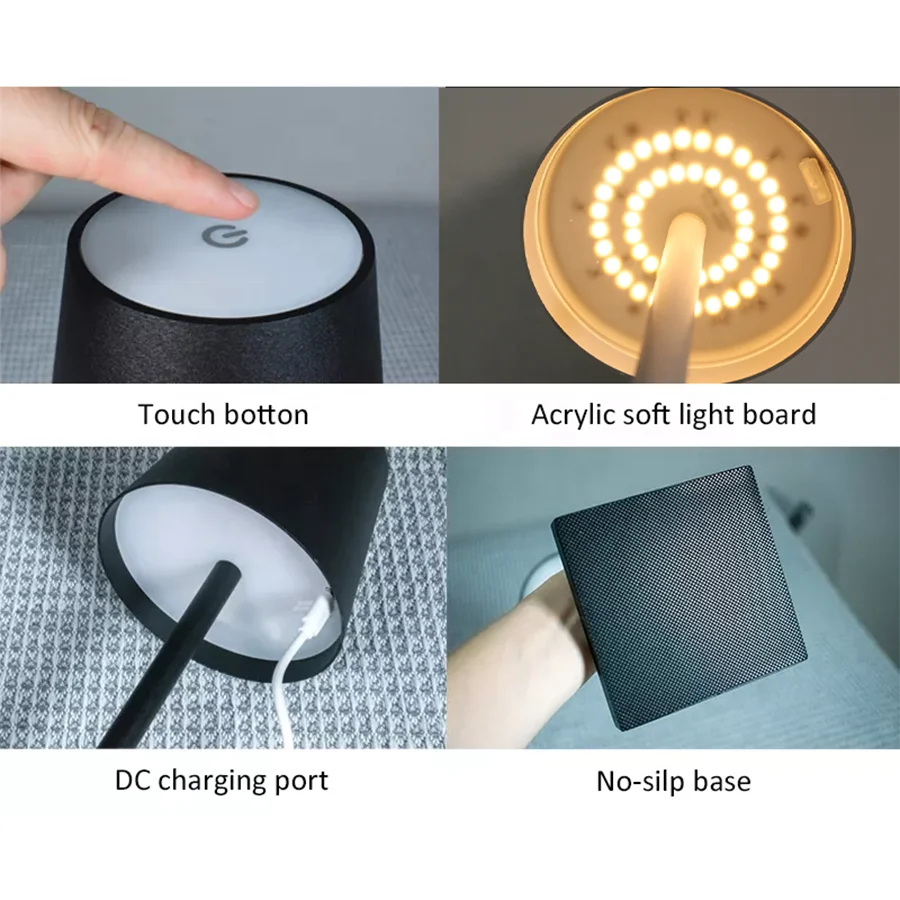

Nom du produit : Lampes de table sans fil |

Type: moderne |

Couleur : Noir/Blanc/OEM |

Matériau : Aluminium/Fer/plastiques |

Source d'alimentation :Fonctionne sur batterie |

Puissance :3.5W |

Mode de commutation: |

Taille du produit : 10*38 |

Capacité de la batterie : 2600Mah/5200mAh |

Classe d'étanchéité : IP54 |

FAQ

Q1 : Quelles sont les conditions de paiement pour les nouveaux clients ?

R : Habituellement, l'assurance commerciale, en option, sera la carte de crédit, le visa, la vérification électronique, Western Union ou T/T.

Q2 : Qu'en est-il du délai de livraison ?

R : 3 à 5 jours pour l'ordre des sentiers et 10 à 15 jours pour la messe.

Q3 : Comment expédiez-vous les marchandises et combien de temps faut-il pour qu'elles arrivent ?

R : Nous expédions généralement par DHL, UPS, FedEx ou TNT. Il faut généralement 3 à 5 jours pour arriver. L'expédition par avion jusqu'à la porte prend environ 15 jours.

Q4 : Puis-je imprimer mon logo sur le luminaire et l'emballage ?

R : Oui, pas de MOQ pour imprimer le logo sur l'appareil et l'emballage.

Q5. Des certifications pour vos produits ?

-- CE, ROHS, PSE, Reach, UKCA etc, afin qu'ils puissent être vendus dans le monde entier en toute sécurité !

Q6. Comment procéder à une commande de lumière LED ?

R : Tout d’abord, faites-nous part de vos besoins ou de votre application. Deuxièmement, nous faisons une offre selon vos exigences ou nos suggestions. Troisièmement, le client confirme les échantillons et verse un acompte pour la commande formelle. Enfin, nous organisons la production.

Q7 : Comment expédiez-vous les marchandises et combien de temps faut-il pour qu'elles arrivent ?

R : Les petites commandes seront expédiées par courrier express international (3 à 7 jours) ou par colis logistique international (15 à 20 jours). Les commandes en gros seront expédiées par avion (5 à 7 jours d'un aéroport à l'autre) et par voie maritime (20 à 40 jours DDP)

Q8.Comment faites-vous pour que notre entreprise soit durable et qu'elle entretienne de bonnes relations ?

-1.prix compétitif pour faire du gagnant-gagnant

-2. Gardez les secrets pour tous nos clients coopératifs

-3. Envoyez de nouveaux remplacements avec votre prochaine commande pour tout produit défectueux.